Library (Part 2): Finding a legend

I find an old man who sells me rough-sawn wood for my cabin-library.

The image that immediately comes to mind when I think about building my library-cabin is cutting wood with an antique handsaw I found in my dad’s shop.

Its handle was hand-carved, dark, and smooth from decades of hard service. The long curving blade was a dull patina of abraded rust. When in my novice hands the blade caught and folded on itself the warp could be gently teased straight over my knee. Its teeth never seemed to dull — or at least I never sharpened them.

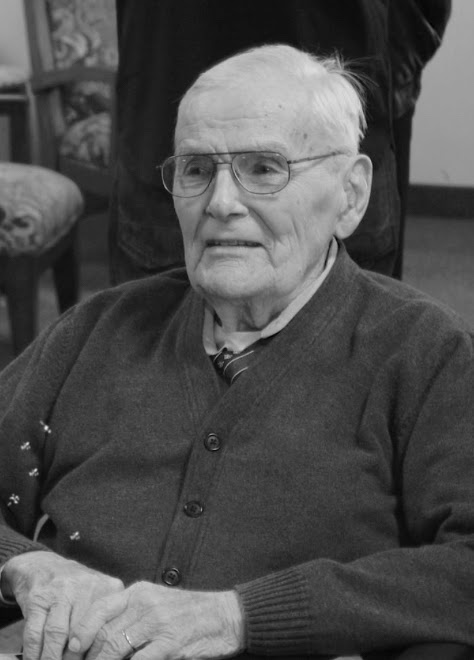

Most of my wood came from a 78-year-old Canadian-turned-American named Lorne Earle Anderson, who, supported by his wife Virginia had a long, storied career of faithful service to both the Canadian military in World War II and in Christian service in their many years following. I went back and read Lorne’s obituary from 2015 and I’m amazed that this old man with shaky hands and a portable sawmill had nearly 20 years to go after we met!

When I met him, he was still leaving his Cambridge, Minnesota 55+ mobile home park each winter for Florida — not to relax — but, as I understood it, to don a welding mask to repair steel tanks for a Christian missionary support organization. This wouldn’t be the last septuagenarian Canadian-American veteran I’d meet with a boyish heart, a love for Jesus, and a penchant for ducks.

The wood Lorne sold me was an ungraded stack of undulating, multi-width oak. But that stack of wood at the end of our gravel driveway was my guarantee of a summer of construction.

I loved the feel of the rough-cut planks. They were knotted and full of splinter-makers. They were curved in one and sometimes two directions, which called for a pressure fit where one arm was using a second small board or hammer to tension a warped 4-inch-wide oak plank into a space meant for a straight one.

Oh, and putting a nail through those nails! I was new to all this. The saw, wood, hammers, tape measures, everything. I learned that you can re-straighten nails by laying them flat on the board that had rejected them and slowly turn the nail like a miniature blacksmith and tapping all the arches down. I also learned to ‘dance’ the nail down by driving the nail back into a straight position by slightly tipping the face of the hammer’s striking edge to meet the head of the nail at the same angle.

Like yesterday, I feel that saw in my right hand and the outside of my left thumb guiding the cutting edge to make a starting cut on the corner of the board. I apply pressure and the saw starts down the line. I blow sawdust off of my pencil line. And I learn to cradle the cutoff piece so it doesn’t fall and splinter the piece I need but not too tight and pinch the blade. When the saw starts to bind up I spray both sides with WD-40.

Too far from any electrics to run a cord, so the whole building will be cut one board at a time. And each one nailed by hand. Before lithium battery tools and LED lights, I got pretty handy with that hammer and saw.

The first and most beautiful moment was creating a roughly 8-by-10-foot platform across my parallel beams on top of the hill. It was a patchwork quilt of boards of all species and colors fit together under pressure and held down by an embarrassing number of bent, but driven, nails.